Curtis D500/D60GT Manual: An Overview

This manual details the operation, maintenance, and troubleshooting of the Curtis D500/D60GT coffee brewing systems, including parts lists (WC-37064, WC-37252) and safety guidelines.

The Wilbur Curtis D500/D60GT coffee brewing system represents a pinnacle of commercial coffee preparation technology. This manual serves as a comprehensive guide for operators, maintenance personnel, and technicians. It details the system’s features, operational procedures, and essential safety precautions.

Understanding this manual is crucial for maximizing brewing performance and ensuring longevity of the equipment. It covers everything from initial setup and standard brewing operations to advanced parameter adjustments and detailed cleaning protocols. Proper use and maintenance, guided by this document, will deliver consistently high-quality coffee.

Target Audience for this Manual

This manual is specifically designed for individuals directly involved with the operation and upkeep of the Curtis D500/D60GT coffee brewing system. The primary audience includes coffee shop managers, baristas, and service technicians responsible for daily operation and routine maintenance.

Additionally, it’s intended for facilities personnel tasked with installation, troubleshooting, and more complex repairs. A basic understanding of commercial coffee brewing equipment and electrical safety is recommended. This guide assumes a moderate level of technical aptitude, providing detailed instructions for all levels of user expertise.

System Components & Identification

This section provides a detailed breakdown of the D500/D60GT’s key parts, including label and UCM kits (WC-37064) and hot water faucet replacements (WC-37252).

D500/D60GT Key Parts Breakdown

The Curtis D500/D60GT brewing system comprises several essential components for optimal performance. These include the brewer housing, water reservoir, heating assembly, and brew funnel. Critical parts needing periodic attention are the silicone seat cup (WC-1806) and various seals.

Understanding each component’s function is vital for effective maintenance. The UCM (User Control Module) manages brewing parameters, while the water filtration system ensures water quality. Proper identification of these parts, alongside associated kit numbers like WC-37064, facilitates efficient repairs and replacements, maximizing the brewer’s lifespan and consistent coffee quality.

Label and UCM Kits (WC-37064)

The WC-37064 kit is a crucial resource for maintaining the visual clarity and operational functionality of your Curtis D500/D60GT brewer. This comprehensive kit includes replacement labels for clear identification of controls and functions. More importantly, it contains the User Control Module (UCM), the brain of the brewing system.

A faulty UCM can disrupt brewing cycles and parameter settings. Replacing it with a new one from the WC-37064 kit restores precise control. Regularly updating labels ensures operators can easily navigate the machine, preventing errors and promoting consistent, high-quality coffee production. This kit is essential for preventative maintenance.

Hot Water Faucet Replacement Kits (WC-37252)

The WC-37252 kit provides all necessary components for a swift and effective hot water faucet replacement on your Curtis D500/D60GT brewing system. A malfunctioning faucet can lead to leaks, inconsistent water delivery, and potential safety hazards. This kit ensures a reliable fix, maintaining optimal brewing performance.

It typically includes a new faucet assembly, seals, and potentially mounting hardware. Replacing a worn or damaged faucet restores accurate temperature control and prevents water wastage. Regular inspection and timely replacement, using this kit, are vital for upholding hygiene standards and extending the lifespan of your brewer.

Installation & Setup

Proper installation and setup are crucial for optimal performance. This section covers initial procedures, ensuring correct water filtration, and verifying electrical connections for the D500/D60GT.

Initial Setup Procedures

Before first use, thoroughly inspect the D500/D60GT for any shipping damage. Carefully unpack all components and verify against the parts list. Connect the brewer to a properly grounded electrical outlet, ensuring voltage compatibility.

Flush the system with clean water to remove any residual debris from manufacturing. Install the appropriate water filter according to the filtration requirements outlined in this manual. Prime the pump by running several brewing cycles with only water.

Confirm all water connections are secure and leak-free. Adjust the brewing parameters to your desired settings, referencing the brewing instructions section for guidance.

Water Filtration Requirements

Optimal brewing performance and longevity of the Curtis D500/D60GT depend on proper water filtration. Hard water and impurities can cause scale buildup, affecting taste and requiring frequent descaling. A compatible filter system is essential.

We recommend a filter capable of reducing chlorine, sediment, and other contaminants. Filter selection should be based on your local water quality. Regularly monitor and replace filters according to the manufacturer’s instructions – typically every 3-6 months, or sooner if water usage is high.

Failure to maintain adequate filtration may void the warranty.

Brewing Instructions

Follow these steps for standard brewing with the Curtis D500/D60GT. Proper operation ensures optimal coffee quality and system performance, as detailed in the manual.

Standard Brewing Operation

To begin, ensure the brewer is properly set up and connected to a filtered water source. Fill the hopper with the desired amount of ground coffee. Select the appropriate brew volume based on your needs, utilizing the system’s controls. Initiate the brewing cycle by pressing the start button, observing the water flow and coffee extraction.

Monitor the brewing process to ensure consistent results. The D500/D60GT automatically controls water temperature and brew time for optimal flavor. Once the brewing cycle is complete, carefully remove the brew container. Regularly check the brewer’s settings and adjust as needed to maintain desired coffee strength and quality.

Adjusting Brewing Parameters

The Curtis D500/D60GT allows for precise control over brewing variables. Adjust brew volume to match desired serving sizes, utilizing the system’s digital interface. Fine-tune coffee-to-water ratios to achieve preferred strength and flavor profiles. Water temperature can be adjusted within a specified range to optimize extraction.

Experiment with pre-infusion settings to enhance bloom and overall coffee quality. Regularly evaluate brewed coffee and make incremental adjustments to parameters. Document changes to maintain consistency. Remember that altering these settings impacts the final brew, requiring careful observation and refinement for optimal results.

Maintenance & Cleaning

Regular cleaning ensures optimal performance and longevity of your Curtis D500/D60GT. Daily procedures, periodic descaling, and hot water faucet replacement (WC-1806) are crucial.

Daily Cleaning Procedures

Consistent daily cleaning is vital for maintaining the quality and lifespan of your Curtis D500/D60GT coffee brewer. After each brewing cycle, immediately flush the brew funnel with hot water to remove coffee grounds and residue. Wipe down the exterior surfaces with a damp cloth, paying attention to areas prone to spills.

Remove and wash the brew basket, filter holder, and any other detachable parts with warm, soapy water. Rinse thoroughly and allow to air dry. Inspect the hot water faucet for any buildup and clean as needed. Proper daily upkeep prevents scaling and ensures consistently delicious coffee.

Periodic Descaling Instructions

Regular descaling is crucial to remove mineral buildup within the Curtis D500/D60GT, ensuring optimal performance and preventing damage. The frequency depends on water hardness; however, monthly descaling is generally recommended. Use a commercially available descaling solution specifically designed for coffee brewers, following the manufacturer’s instructions carefully.

Run the descaling solution through a full brew cycle, then follow with several cycles of fresh water to thoroughly rinse the system. Neglecting descaling can lead to reduced brewing efficiency and compromised coffee flavor. Always consult the manual for specific descaling guidelines.

Replacing the Hot Water Faucet (WC-1806)

To replace the hot water faucet (WC-1806) on your Curtis D500/D60GT, begin by disconnecting the power supply. Carefully remove the existing faucet, noting the position of any seals or O-rings. Install the new faucet, ensuring a secure fit and proper alignment. Utilize a silicone seat cup (WC-1806) for optimal sealing.

Reconnect the water lines and thoroughly test for leaks before restoring power. Replacement kits (WC-37252) are available for convenience. Improper installation can lead to scalding hazards; proceed with caution and refer to the service manual for detailed instructions.

Troubleshooting

This section provides solutions for common issues and explains error codes encountered with the Curtis D500/D60GT. Refer to the manual for detailed diagnostics.

Common Issues and Solutions

Addressing typical problems ensures optimal performance of your Curtis D500/D60GT. If the brewer isn’t heating, check the electrical connection and breaker. For slow brewing, verify water filtration isn’t clogged and descale regularly.

Low water flow often indicates a filter issue or scale buildup. If the hot water faucet malfunctions, replacement kits (WC-37252) are available. Always ensure proper grounding for electrical safety. Refer to the error code section for specific diagnostics. Regular cleaning prevents many issues, extending the brewer’s lifespan and maintaining coffee quality.

Error Codes and Their Meanings

Decoding error messages is crucial for efficient troubleshooting of your Curtis D500/D60GT. While specific codes vary, common issues include low water detection, overheating, or pump failures. A flashing light often indicates a sensor problem requiring inspection.

Consult the full service manual for a comprehensive list and corresponding solutions. Ignoring error codes can lead to further damage. Regularly check connections and water lines. Proper maintenance minimizes error occurrences. Contact Wilbur Curtis support if unfamiliar with interpreting codes or implementing repairs.

Safety Precautions

Always follow electrical safety guidelines and operational warnings when using the Curtis D500/D60GT. Disconnect power before servicing and avoid hot surfaces during operation.

Electrical Safety Guidelines

Prior to any maintenance or servicing, always disconnect the Curtis D500/D60GT from the electrical power source. Never operate the unit with a damaged power cord or plug. Ensure proper grounding to prevent electrical shock hazards.

Do not expose electrical components to water or other liquids. Qualified personnel should perform all electrical repairs. Adhere to local and national electrical codes during installation and operation. Regularly inspect the power cord for wear and tear, replacing it if necessary.

Avoid using extension cords; if required, use a heavy-duty cord rated for the brewer’s amperage. Improper electrical connections can lead to fire or equipment damage.

Operational Safety Warnings

Exercise caution when handling hot water and brewed coffee from the Curtis D500/D60GT, as severe burns can occur. Never operate the brewer without water, as this can damage the heating elements. Ensure the drip tray is properly positioned to prevent spills and potential hazards.

Do not attempt to disassemble or modify the brewing system beyond the procedures outlined in this manual. Regularly inspect hoses and connections for leaks. Keep hands and other objects away from moving parts during operation.

Always use appropriate personal protective equipment, such as gloves, when cleaning or performing maintenance.

Technical Specifications

The Curtis D500/D60GT requires specific electrical configurations (120V) and water consumption rates, detailed within this manual for optimal performance and safety.

D500/D60GT Electrical Requirements

The Curtis D500/D60GT coffee brewing system is typically configured for 120V electrical service. However, specific voltage requirements may vary depending on the model and regional standards. Always verify the voltage indicated on the unit’s data plate before connecting to a power source.

Improper voltage can cause serious damage to the brewer and void the warranty. Ensure the electrical circuit is adequately grounded and protected by a suitable circuit breaker or fuse. Consult a qualified electrician if you are unsure about the electrical requirements or installation procedures. Adherence to these guidelines is crucial for safe and reliable operation.

D500/D60GT Water Consumption

The Curtis D500/D60GT coffee brewing system’s water consumption varies based on brewing volume and settings. Proper water filtration is essential for optimal performance and longevity of the machine. Utilizing filtered water minimizes scale buildup and ensures the best-tasting coffee.

Regular monitoring of water usage helps identify potential leaks or malfunctions. The system requires a consistent water supply with adequate pressure for efficient brewing. Refer to the installation section for specific water pressure recommendations. Maintaining appropriate water quality and pressure is vital for consistent brewing results.

Parts Ordering Information

Genuine Curtis replacement parts (like WC-37064, WC-37252) ensure optimal performance and longevity. Contact Wilbur Curtis support for assistance with locating and ordering needed components.

Locating Replacement Parts

Securing genuine Wilbur Curtis replacement parts is crucial for maintaining the performance and extending the lifespan of your D500/D60GT brewing system. Begin by referencing the parts diagrams within this manual to identify the specific component needed. Key part numbers, such as WC-37064 (Label & UCM Kit) and WC-37252 (Hot Water Faucet Replacement Kit), are essential for accurate ordering.

Authorized Curtis distributors are an excellent resource, offering readily available parts and expert advice; Alternatively, you can directly contact Wilbur Curtis support with your model number and part details. Always verify compatibility before finalizing your purchase to ensure a proper fit and function.

Contacting Wilbur Curtis Support

For dedicated assistance with your Curtis D500/D60GT coffee brewing system, Wilbur Curtis offers comprehensive support channels. Direct inquiries regarding parts, troubleshooting, or warranty claims to their customer service team. While specific contact details aren’t provided in the excerpts, searching “Wilbur Curtis Support” online will yield current phone numbers, email addresses, and potentially a live chat option.

Having your brewer’s model number and serial number readily available will expedite the support process; Be prepared to describe the issue in detail, including any error codes displayed. Their knowledgeable representatives can guide you through diagnostics and provide solutions or facilitate parts ordering.

Warranty Information

The Curtis D500/D60GT brewers are covered by a manufacturer’s warranty, details of which are available upon request. Warranty claims require specific procedures for validation.

Warranty Coverage Details

The Wilbur Curtis warranty safeguards against defects in materials and workmanship under normal use. This coverage extends for a defined period from the original purchase date, varying by component. Parts like the hot water faucet (WC-1806) and those within label/UCM kits (WC-37064) may have specific durations.

The warranty does not cover damage resulting from improper installation, inadequate water filtration, unauthorized repairs, or misuse. Regular maintenance, including descaling, is crucial to maintain warranty validity. Labor costs for repairs are typically not included, and shipping charges for returned parts are the responsibility of the owner.

Warranty Claim Procedures

To initiate a warranty claim, contact Wilbur Curtis support with proof of purchase (date and invoice). Clearly describe the issue, including the model (D500/D60GT) and any relevant part numbers (e.g., WC-37064, WC-37252, WC-1806).

Curtis may request photos or return of the defective part for inspection. All returns must be authorized and shipped with a Return Merchandise Authorization (RMA) number. Shipping costs are the claimant’s responsibility. Upon verification of the defect, Wilbur Curtis will, at its discretion, repair or replace the faulty component.

Diagrams & Visual Aids

Detailed system component diagrams and brewing cycle illustrations are provided for visual reference, aiding in understanding the D500/D60GT’s assembly and operation.

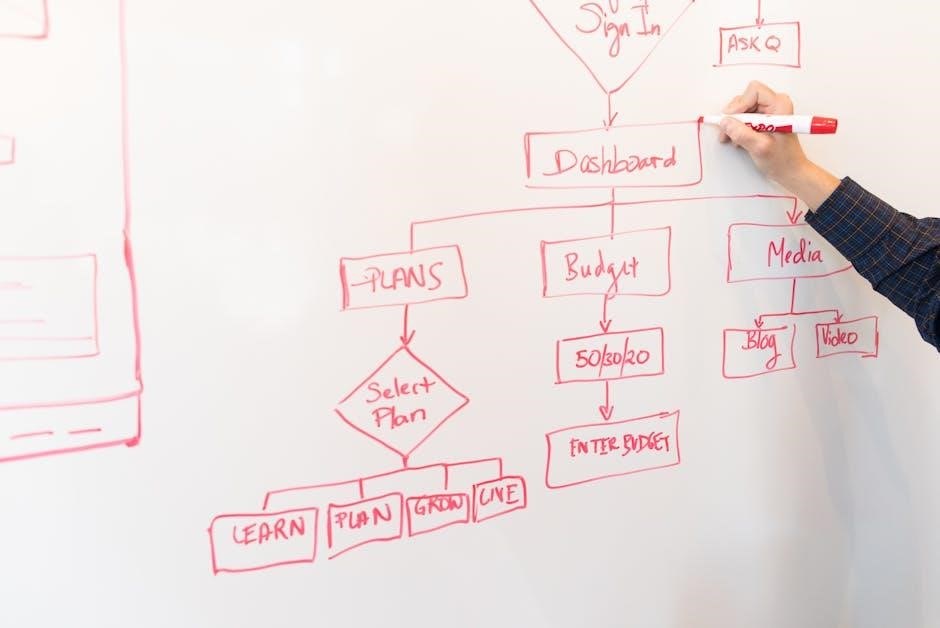

System Component Diagram

The system component diagram visually breaks down the Curtis D500/D60GT coffee brewing system into its individual parts. This detailed illustration highlights key components like the water inlet, brew chamber, hot water faucet (WC-1806), and associated plumbing.

Labels clearly identify each part, facilitating easier maintenance and repair procedures. The diagram also showcases the location of the label and UCM kits (WC-37064), and hot water faucet replacement kits (WC-37252). Understanding this diagram is crucial for identifying parts during ordering and troubleshooting. It provides a comprehensive overview of the brewer’s internal structure.

Brewing Cycle Illustration

The brewing cycle illustration provides a step-by-step visual representation of the Curtis D500/D60GT’s brewing process. It details the flow of water from the reservoir, through the heating element, and into the brew chamber.

Each stage is clearly depicted, showcasing the pre-infusion, brewing, and post-brew phases. This illustration aids in understanding the timing and sequence of operations, crucial for adjusting brewing parameters and diagnosing potential issues. It visually explains how the system delivers hot water for optimal coffee extraction. Referencing this diagram during operation ensures consistent brewing results.